Flexibility is the Key

Flexibility is the Key

When we think of flexibility, we often think of finished goods. However, there are a lot of factors in which the right partner can offer flexibility. From Engineering support to collaboration on inbound logistics through the buffering of component stocks either with your partner or buffered at the supplier through a negotiated agreement.

Planning an optimised scheduling of your supply chain will often dictate how flexible you can be with your customers, so getting it right is paramount.

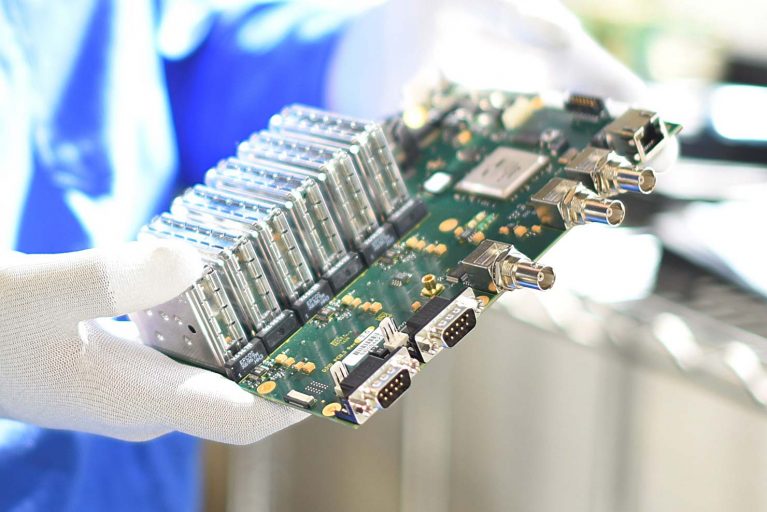

At NOTE we work with our customers and supply chain at both the design stage, and throughout the life-cycle of a product. Procurement, materials sourcing and inventory management is crucial to the success of meeting customer required delivery dates.

We operate both offshore and near-shore sourcing strategies to complement our local procurement, which results in our customers often having blended solutions, and the best of both worlds.

With demand often difficult to predict, it is easy to get into the ‘Just in Case’ mentality where you order parts and manufacture too many goods just to make sure you cover your customer demand. With our Kanban system, the ‘Just in Case’ mentality is eliminated, and products are manufactured when required using a pull, not push model. Our well-engineered Kanban system self regulates by pulling higher level build when demand dictates and conversely slows up when demand falls. Meaning we never waste your valuable resources.

Combine this with our build to order (BTO) and configure to order (CTO) services, where we Kanban at sub-assembly levels and then manufacture finished product to order. By offering these services and capabilities we can provide resilience to disruptions in supply in both short and medium term ensuring key objectives to delivery and technology continue to be met.