Functional Test

Functional Test

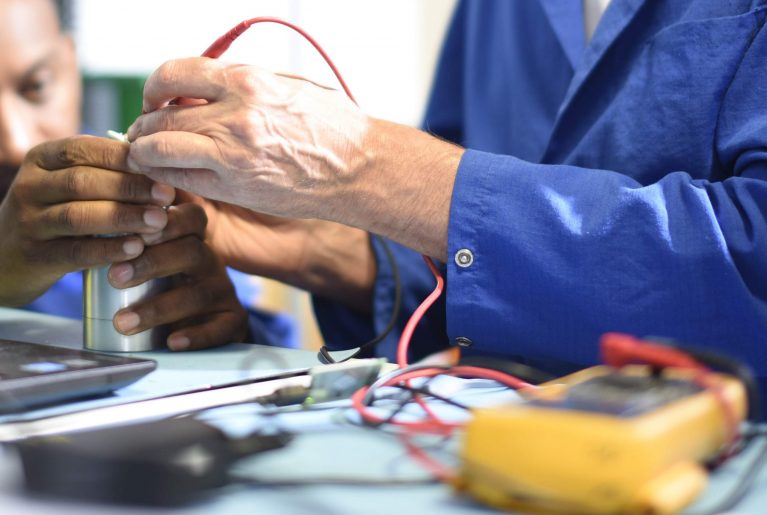

Functional Test is often needed as a proof that the assembly or unit conforms to specification. However, as a production test tool it is poor. Cheap to set up, but costly to operate due to test times and fault finding. Test rigs are often not fit for purpose, break down often and can’t cope when a faulty assembly is plugged in.

Ideally functional test should be part of a test strategy and the last phase of the production line i.e. Other forms of PCBA testing should be used initially to ensure boards are free of assembly errors and then tested functionally as a unit to ensure the item meets specification.

Functional Test at a glance

Set Up Costs

- Normally one of the lowest as it tends to be your equipment made into a rig

Speed

- OK to Poor test speed

- Many minutes normally

Coverage

- Excellent

- Depends on how much you specify

Operator Level Required

- OK

- Technical knowledge is normally needed

Fault Finding

- Poor

- By far the biggest weakness

- Most functional testing gives a pass or

fail result with no help offered for fault finding

Running Cost

- Low cost of ownership, but a high cost due to operator level and fault finding issues

“They provide excellent service, with professionalism, great quality and the set up is top level. Personal service – feels like dealing with a small company but they have the corporate support and backing. They have nailed it.”